Lily Mckeown | 11 November 2025

Engineering for the UK’s Offshore and Renewable Future

The UK’s energy landscape is changing fast. Offshore wind farms, tidal schemes and innovative marine renewable projects are pushing further from shore, into deeper waters and harsher environments. Behind the scenes, hydraulic systems are doing the heavy lifting, controlling motion, managing loads and keeping critical equipment moving safely and reliably.

DHX is proud to be part of that transition. Drawing on decades of industrial hydraulic expertise, we engineer systems built for the unique demands of offshore and renewable applications, helping project developers, vessel operators and equipment OEMs deliver dependable performance where it matters most: at sea.

Challenges at Sea: Corrosion, Pressure and the Elements

Operating offshore is a world away from a controlled factory floor. Hydraulic systems in marine and renewable environments must contend with:

Relentless corrosion – Salt-laden air, sea spray and immersion all attack exposed metal surfaces, fittings and fasteners.

High static and dynamic loads – Offshore handling systems, lifting equipment, jack-up mechanisms and tensioners experience extreme forces, shock loads and fatigue from waves, wind and vessel motion.

Pressure and depth – Subsea and near-subsea equipment must operate reliably under hydrostatic pressure, with sealed components that remain tight over time.

Temperature swings – Equipment can face rapid changes in temperature and weather, impacting oil viscosity, seal performance and control behaviour.

Access and maintainability – Once installed offshore, access is difficult, weather windows are short and intervention costs are high. Systems must be designed to run reliably between service visits and to be straightforward to maintain when the opportunity comes.

These conditions demand hydraulic solutions that are not just robust on paper, but thoroughly engineered to withstand the realities of the marine environment. That’s where DHX’s design approach comes in.

Orbital Marine Power O2 – Hydraulics for Tidal Power

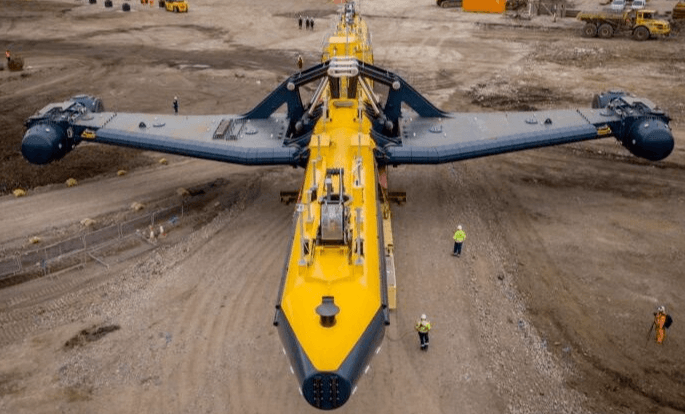

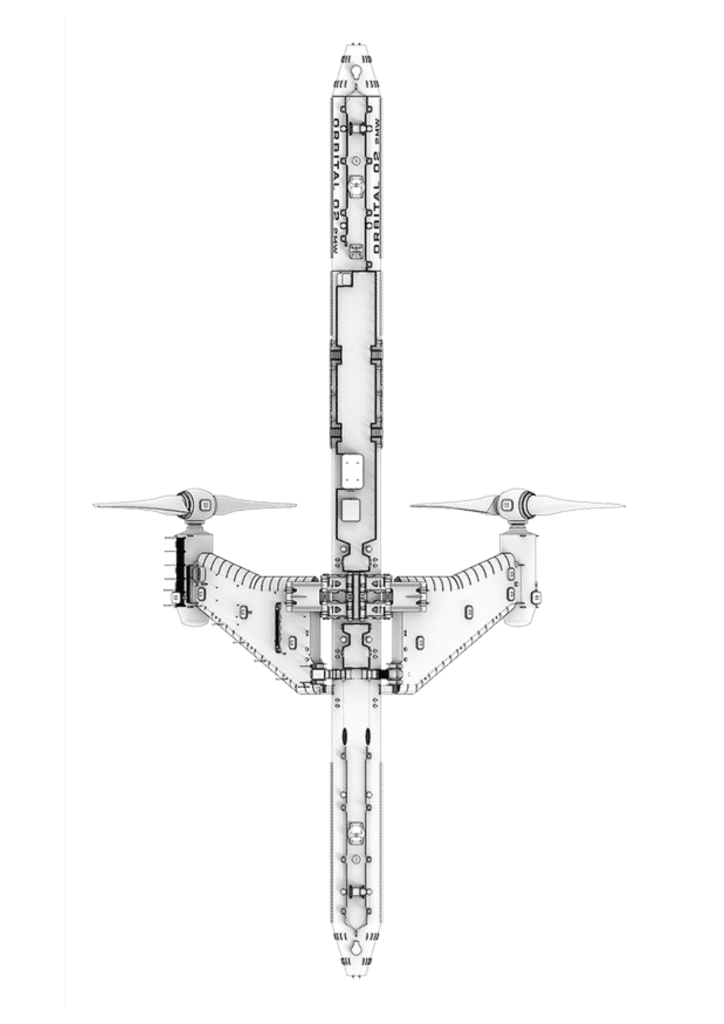

A standout example of DHX’s offshore renewable capability is our work on Orbital Marine Power’s O2 tidal turbine, the company’s third-generation floating device. The O2 is a 72-metre, 680-tonne platform that sits in the powerful tidal currents around Orkney, using 20-metre turbine blades on retractable legs to generate up to 2 MW of clean electricity, enough to power thousands of homes.

Orbital Marine Power asked DHX to develop a bespoke on-board hydraulic system with two critical functions: tensioning the seabed anchors that hold the O2 on station, and deploying and retracting the turbine support legs that lower the blades into the tidal flow or lift them clear of the water for maintenance.

DHX engineered a high-pressure hydraulic solution that combines a 75 kW variable speed drive with a variable displacement pump, powering both the retractable leg cylinders and dual-speed winches for the mooring system. This provides smooth, controllable motion with efficient acceleration and deceleration for both anchoring and leg deployment.

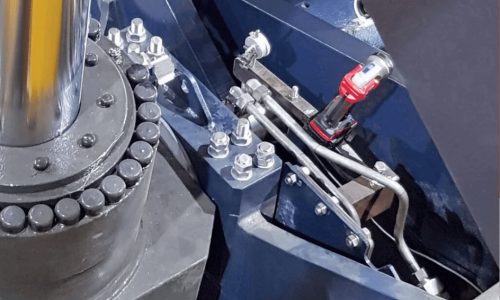

The design also addressed a key offshore reliability risk: external hydraulic hoses vulnerable to debris and harsh conditions. DHX reworked the turbine leg hinge so hydraulic oil passes through the trunnion pin via a rotary union, eliminating external hoses and allowing critical load-control valves to be housed inside the hull. Leg cylinders are synchronised with a rotary flow divider for precise leg positioning, optimising power generation and simplifying in-situ servicing. In maintenance mode, the legs can lift the turbines to the surface, easing towing, inspection and repair.

The O2 project shows how DHX’s hydraulic engineering supports cutting-edge marine renewables, delivering robust, maintainable systems.

Sustainability Through Engineering

Offshore and renewable projects exist to deliver cleaner energy – and good hydraulic engineering has a direct role to play in that mission.

Reliable, efficient hydraulic systems:

Reduce unplanned vessel time and rework, cutting fuel use and associated emissions from installation and maintenance campaigns.

Improve energy efficiency on vessels and platforms by optimising pump control, minimising leakage and pressure losses, and reducing unnecessary heat generation.

Extend equipment life, which lowers material consumption, reduces waste and avoids the carbon cost of premature replacements.

By designing hydraulic systems that last longer, waste less energy and are easier to maintain, DHX supports the broader sustainability goals of offshore and renewable operators. Clean energy isn’t just about turbines and generators – it’s about every supporting system working efficiently and responsibly.

A Call to Collaborate: Partnering with Renewable Innovators

Offshore and renewable projects demand close collaboration between developers, OEMs, integrators and specialist suppliers. DHX is ready to be your hydraulic engineering partner in that mix.

Whether you’re:

Developing a new offshore handling or positioning system,

Refining an existing design for harsher environments or deeper water, or

Looking to upgrade legacy hydraulics to meet modern safety, reliability and sustainability expectations,

We can help turn concepts into robust, service-ready solutions.

If you’re working at the forefront of offshore wind, tidal, wave or other marine renewable technologies and need hydraulics that can power the next wave of innovation, get in touch with DHX.

Let’s explore how our engineering experience can support your next offshore or renewable project.

If you’re planning your next project, get in touch with us today to leverage your hydraulic expertise and secure a safer, more reliable future for your operation.