Lily Mckeown | 11 November 2025

When heavy duty hydraulic systems fail, the clock starts ticking and every minute of downtime costs money. Lost productivity, delayed operations, emergency repairs and safety risks all compound into far bigger expense than most organisations expect. That’s why proactive, planned maintenance isn’t just a nice-to-have; its one of the smartest investments

In today’s high-demand industrial landscape, the companies that stay ahead of failure stay ahead of the competition. And that starts with a solid maintenance strategy.

The Hidden Power of Prevention

Hydraulic systems are incredibly powerful but just as sensitive to wear, contamination and operating conditions. Many failures don’t happen suddenly , they develop silently over time. Small leaks, pressure fluctuations, deteriorating seals or fluid contamination can escalate into catastrophic breakdowns if not addressed early.

Routine maintenance dramatically reduces this risk. With scheduled inspections and timely servicing, operations can:

DHX Maintenance, service that runs deeper

At DHX, maintenance isn’t just a checkbox, its a comprehensive lifecycle support philosophy designed to keep hydraulic systems operating at peak performance.

Thorough Inspections

Our team conduct complete system checks, including fluid analysis, component wear assessments, leak detection and performance benchmarking . These inspections identify issues early so you can address them with minimal disruption.

Expert Servicing

From seal replacements to filter changes and system recalibration, we apply industry-leading service standards backed by decades (60 years to be precise) of hydraulic expertise. Every service we do is performed with precision to ensure our equipment continues to operate reliably and efficiently.

Complete Overhauls

When systems reach the point where a refresh is needed, DHX provides full overhauls including disassembly, refurbishment, reassembly and testing. Each overhaul returns equipment to near-new performance while extending its working life.

Customer Benefits: Why It Pays To Maintain Proactively

Investing in planned maintenance delivers measurable returns across your entire operation:

Boosted ROI

Well-maintained systems operate more efficiently, consume less energy and require fewer expensive emergency repairs. That adds up to a stronger return on investment and predictable budgeting.

Improved Safety

Hydraulic failures can be dangerous. Regular inspections and servicing reduce the risks of leaks, bursts or mechanical faults that could jeopardise work safety.

Extended Equipment Life

Routine care helps equipment run longer, delaying costly replacements and ensuring that every asset delivers maximum value over its lifespan.

Reduced Downtime

The biggest win of all: your operation keeps moving with no interruptions. Planned maintenance minimises unplanned shutdowns and keeps that productivity where it should be – at peak performance.

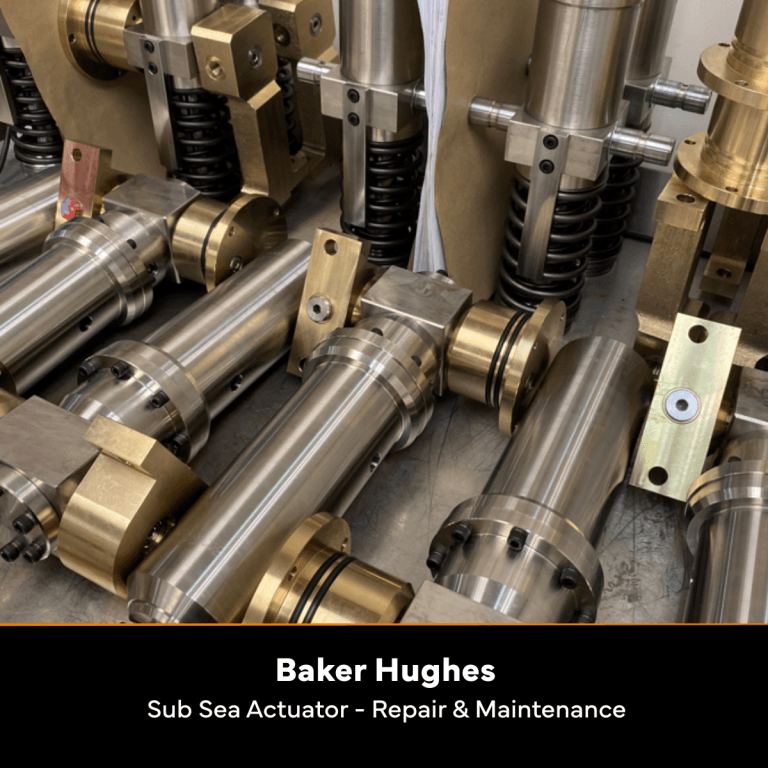

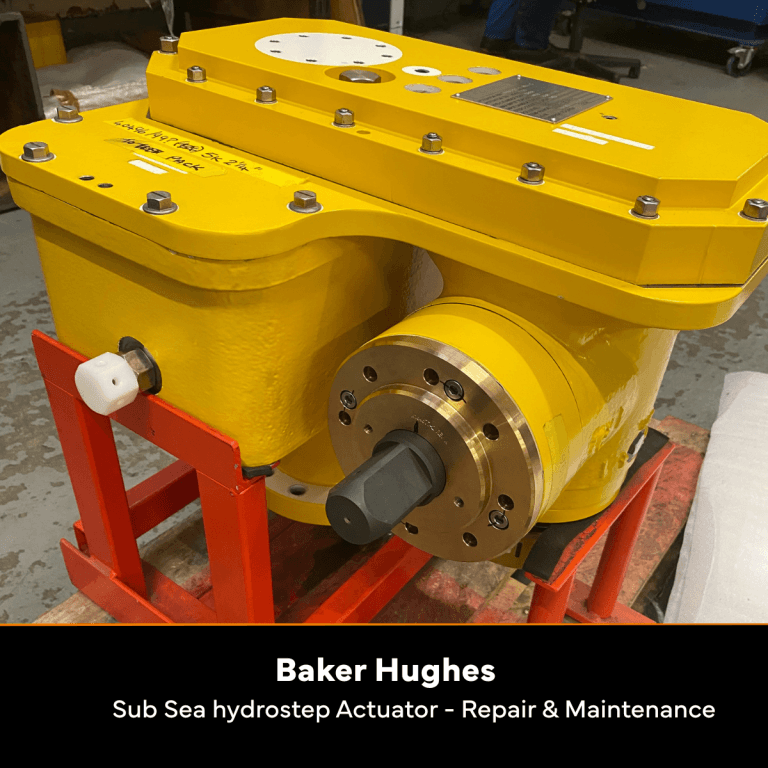

Maintenance Currently Underway in the Workshop

Isle of Man – Peel Harbour

The hydraulic swing bridge and hydraulic lowering flap gate have operated reliably for 22 years. The cylinders recently returned for repair will be fully stripped and inspected by DHX, who will provide a detailed condition report to the client. Upon receiving approval, DHX will proceed with the refurbishment, including replacement of all worn parts, installation of new seal kits, full retesting, and repainting.

We keep your performance at it’s peak.