Lily Mckeown | 12 December 2025

Hydraulic cylinders remain one of the most essential components in today’s industrial and commercial machinery. From heavy construction equipment to everyday municipal vehicles, these compact yet powerful devices make it possible to lift, push, press, steer and control with precision.

Although the basic operating principle of a hydraulic cylinder has not changed, fluid pressure generating linear motion, the engineering behind modern systems has advanced significantly. Today’s cylinders are more efficient, more durable and more customisable than ever before.

How Hydraulic Cylinders Work

At their core, hydraulic cylinders operate on Pascal’s Law: when pressurised fluid is applied to a confined area, it creates force. Inside each cylinder:

A sealed barrel holds hydraulic fluid (typically oil or environmentally safe alternatives).

A piston and rod assembly sit within the barrel, capable of moving linearly.

When pressurised fluid enters the chamber, the piston extends or retracts, producing controlled mechanical force.

Because the force generated is a direct product of the piston surface area and the internal pressure, these cylinders are capable of producing tremendous power from relatively compact units.

Where Hydraulic Cylinders Are Used Today

Waste & Recycling Equipment

Refuse collection vehicles use hydraulic systems to compact waste, while recycling facilities depend on hydraulic presses to compress scrap metal, plastics and other materials.

Aerospace & Aviation

Hydraulics power landing gear, braking systems, flap controls and other critical aircraft mechanisms that demand reliability and precision.

Sports Stadia & Large Moving Structures

Modern stadiums increasingly rely on hydraulics to support ambitious architectural designs. One of the most famous examples is the Tottenham Hotspur Stadium, whose fully retractable pitch uses an advanced hydraulic system to seamlessly separate, raise, and slide the natural grass pitch beneath the artificial NFL pitch. This level of precision, power and reliability simply wouldn’t be achievable without heavy-duty hydraulic cylinder assemblies.

Mining & Oil and Gas

These demanding environments require cylinders capable of withstanding high loads, extreme temperatures, and harsh operating conditions.

Manufacturing & Materials Handling

Production lines rely on cylinders for pressing, forming, moulding, lifting and automation tasks.

Key Benefits of Modern Hydraulic Cylinders

Exceptional Power Density

Hydraulic cylinders extremely high force relative to their size. This makes them ideal for applications where immense strength is required but space is limited.

Smooth, Precise Control

Modern hydraulic designs allow for accurate speed, pressure and movement control, perfect for both delicate operations and heavy-duty tasks.

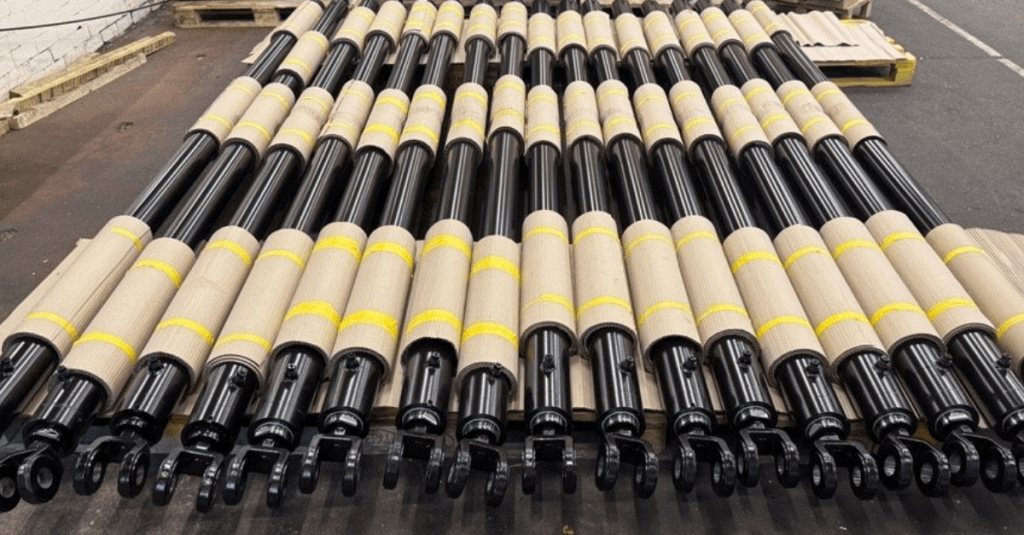

Versatility & Custom Engineering

Cylinders can be manufactured in custom lengths, bore sizes, mounting types, and pressure ratings. Options include:

Bespoke stroke lengths

Specialist mounting configurations

Various seal materials

A range of hydraulic fluids, including mineral oil and water-glycol variants

This adaptability ensures a perfect fit for diverse industries and specialised projects.

Durability & Safety

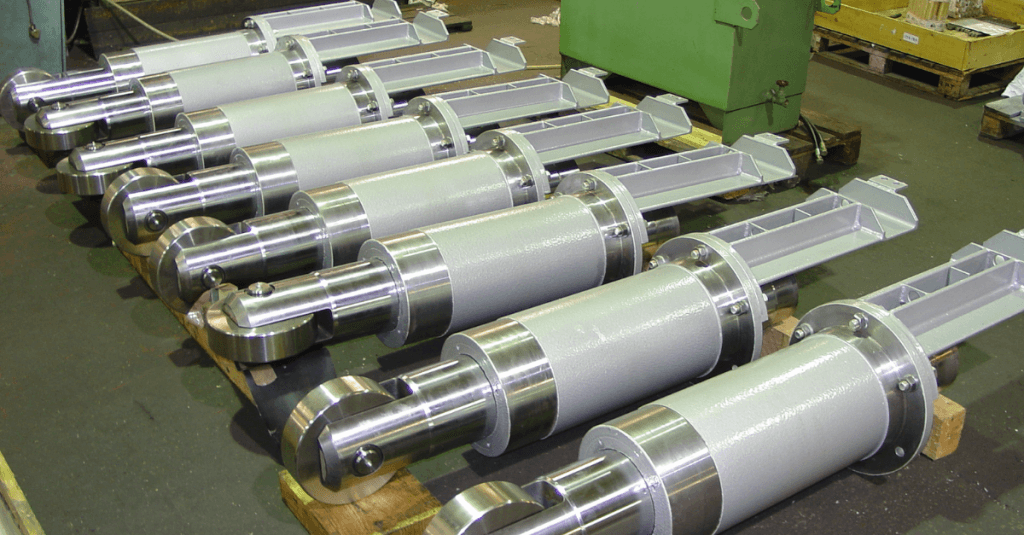

With advanced metallurgy, high-quality seals, and precision engineering:

Wear and tear is minimised

Pressure relief systems enhance safety

Fewer moving parts reduce maintenance needs

Reliability is significantly improved, even in demanding environments

Whether it’s a standard cylinder or a bespoke unit engineered for highly specific use cases, modern hydraulic systems are built to deliver long-term performance.

Why High-Quality Cylinder Manufacturing Matters

Manufacturers who specialise in hydraulic engineering including custom and application-specific cylinders play a crucial role in ensuring equipment safety, efficiency and durability. Precision machining, quality materials and rigorous testing standards are what make hydraulic systems dependable in mission-critical situations.

From construction sites to aircraft landing gear and even cutting-edge stadium architecture, well-designed cylinders ensure smooth operation, minimise downtime and support the demanding needs of modern industries.

If you’re exploring hydraulic cylinders for a new project or seeking replacements for existing machinery, professional guidance can make all the difference.

Reach out to discuss your requirements, request a quote or learn more about the latest advancements in hydraulic cylinder design below.